In today’s competitive mobile accessory market, businesses are constantly seeking innovative tools to gain an edge. One such tool that’s rapidly transforming the industry is the screen protector machine. If you are looking for a way to increase efficiency, improve product quality, and boost sales fast, investing in a screen protector machine might be your best move.

In this comprehensive article, we’ll explore what a Screen protector machine is, how it works, and why it’s a must-have for businesses aiming to scale quickly. You’ll also discover key benefits, practical tips for choosing the right machine, and answers to common questions.

What Is a Screen Protector Machine?

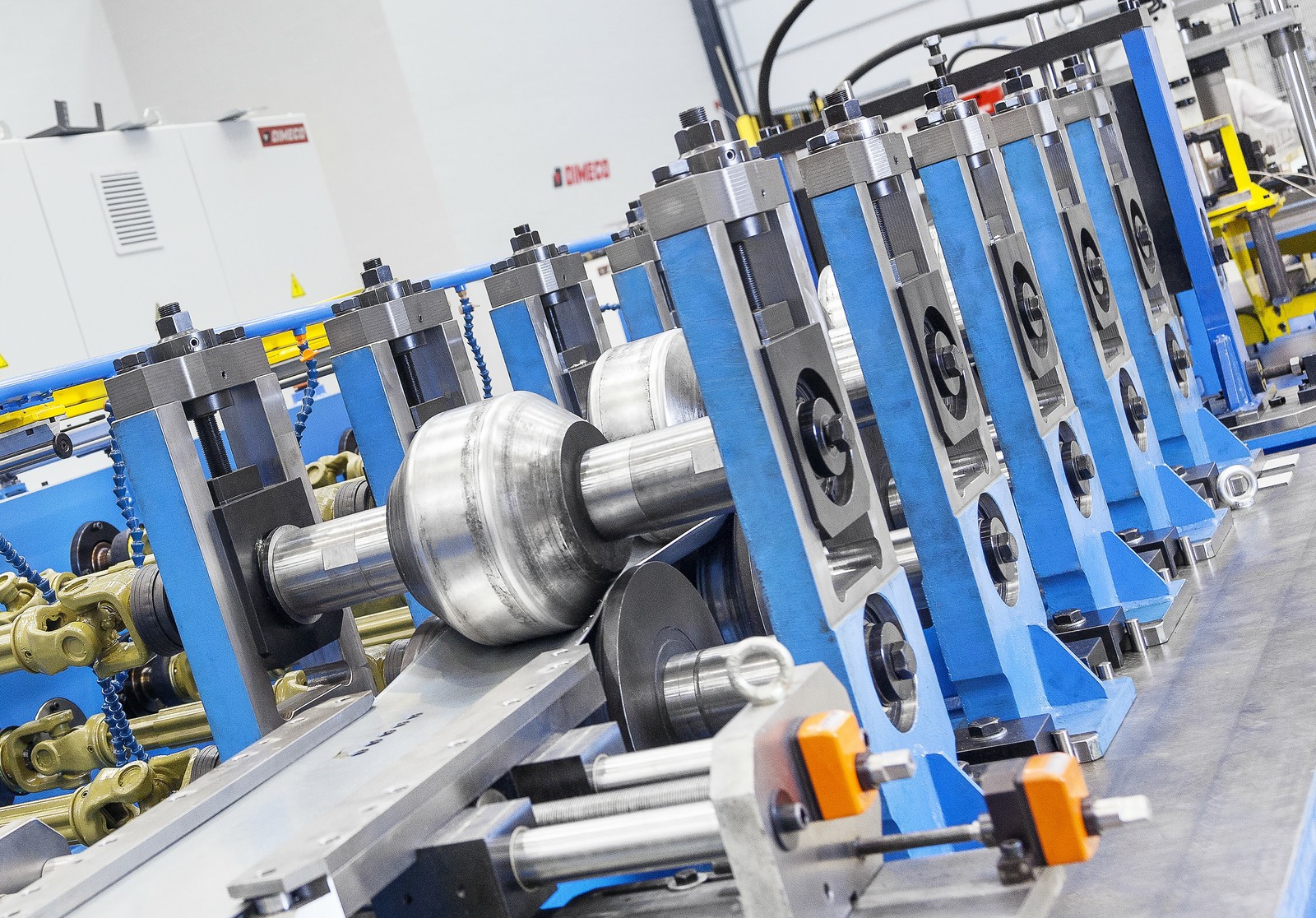

A screen protector machine is a specialized device designed to cut, shape, and sometimes apply protective films to electronic device screens such as smartphones, tablets, and laptops. It automates and streamlines the manufacturing or customization process of screen protectors, ensuring precision, speed, and high-quality results.

Unlike manual cutting or application, a screen protector machine uses advanced technology such as laser cutting, CNC routing, or automated lamination. This reduces errors and waste while enabling businesses to fulfill large orders efficiently.

How Does a Screen Protector Machine Boost Sales Fast?

1. Increased Production Speed

One of the main advantages of a screen protector machine is the dramatic increase in production speed. By automating repetitive tasks like cutting and applying screen protectors, businesses can handle higher order volumes without sacrificing quality.

2. Consistent Quality

Inconsistent product quality can lead to customer dissatisfaction and returns. A screen protector machine ensures uniform cuts and flawless application, boosting customer confidence and encouraging repeat purchases.

3. Cost Efficiency

Automating screen protector production reduces labor costs and minimizes material waste. Lower production costs allow businesses to offer competitive prices, attracting more customers and increasing sales rapidly.

4. Customization Capabilities

Modern screen protector machines often allow for customization, including bespoke sizes and shapes tailored to niche or new devices. This flexibility helps businesses cater to a broader market segment and meet evolving customer demands.

5. Reduced Turnaround Time

Faster production leads to quicker order fulfillment. This can enhance your reputation for reliability and prompt delivery, key factors that influence customer purchasing decisions.

Key Features to Look for in a Screen Protector Machine

When selecting a screen protector machine, consider these critical features to maximize your return on investment:

- Precision Cutting: Look for laser or CNC cutting options for exact measurements.

- Speed: Higher cutting speed means quicker order processing.

- User-Friendly Interface: Easy-to-use controls reduce training time and errors.

- Material Compatibility: Ensure the machine can handle various materials like tempered glass and PET films.

- Size Flexibility: Ability to cut different screen sizes to accommodate various devices.

- Durability and Maintenance: Opt for machines with robust build quality and straightforward maintenance.

How to Integrate a Screen Protector Machine into Your Business

To boost sales fast with a screen protector machine, integration is key. Here’s how to do it effectively:

Step 1: Assess Your Production Needs

Analyze your current production volume and future growth projections. This will help you choose a machine with the appropriate capacity and features.

Step 2: Train Your Team

Even the most advanced machine requires skilled operators. Provide thorough training to maximize machine efficiency and minimize errors.

Step 3: Optimize Workflow

Integrate the machine smoothly into your production line. Identify bottlenecks and redesign processes to take full advantage of the machine’s speed.

Step 4: Market Your Enhanced Capabilities

Leverage your new machine as a selling point in your marketing materials. Highlight faster turnaround times, improved quality, and customization options.

Step 5: Monitor and Improve

Regularly track performance metrics such as production speed, defect rates, and customer feedback. Use this data to optimize machine settings and workflow continuously.

Benefits of Using a Screen Protector Machine

Enhanced Productivity

A screen protector machine can cut production times by up to 70%, allowing your business to handle more orders without expanding your workforce.

Higher Profit Margins

Automation reduces labor and material costs, translating into better profit margins.

Improved Customer Satisfaction

Accurate cuts and flawless application mean fewer defects, resulting in happier customers and fewer returns.

Competitive Advantage

By offering customized and rapid screen protector solutions, your business stands out in a crowded marketplace.

Common Types of Screen Protector Machines

- Laser Cutting Machines: Use laser beams for precise and clean cuts.

- CNC Machines: Computer-controlled routers that carve out shapes with high accuracy.

- Lamination Machines: Combine cutting with automatic film application.

- Automatic Application Machines: Designed specifically for applying screen protectors perfectly without bubbles or dust.

Frequently Asked Questions (FAQ)

1. How does a screen protector machine improve product quality?

A screen protector machine ensures precise, clean cuts and uniform application of protective films. This reduces defects and enhances the overall finish, improving customer satisfaction.

2. Can a screen protector machine handle different device sizes?

Yes, most modern machines offer size flexibility and can be adjusted or programmed to cut screen protectors for various devices, including smartphones, tablets, and laptops.

3. Is investing in a screen protector machine cost-effective for small businesses?

While the initial investment may be significant, the long-term benefits such as increased production speed, reduced waste, and higher product quality make it a worthwhile investment, even for small businesses aiming to grow.

Conclusion: Invest in a Screen Protector Machine to Boost Sales Fast

In the fast-paced mobile accessories industry, staying ahead means embracing technology that delivers speed, precision, and quality. A screen protector machine is not just a tool; it’s a strategic asset that can transform your production process and boost sales fast. From expert tips to trending updates, it’s all available on our main page.

Leave a Reply