In today’s competitive manufacturing landscape, achieving zero defects is no longer a luxury—it’s a necessity. Companies are under constant pressure to deliver flawless products while optimizing production efficiency. Enter machine vision systems, a technological breakthrough that is transforming quality assurance processes worldwide. At Sciotexe, we understand the pivotal role of machine vision in driving defect-free manufacturing.

This article delves into how advanced machine vision systems empower manufacturers to achieve zero defects, the technology behind these systems, and the benefits they offer across various industries.

What is Machine Vision?

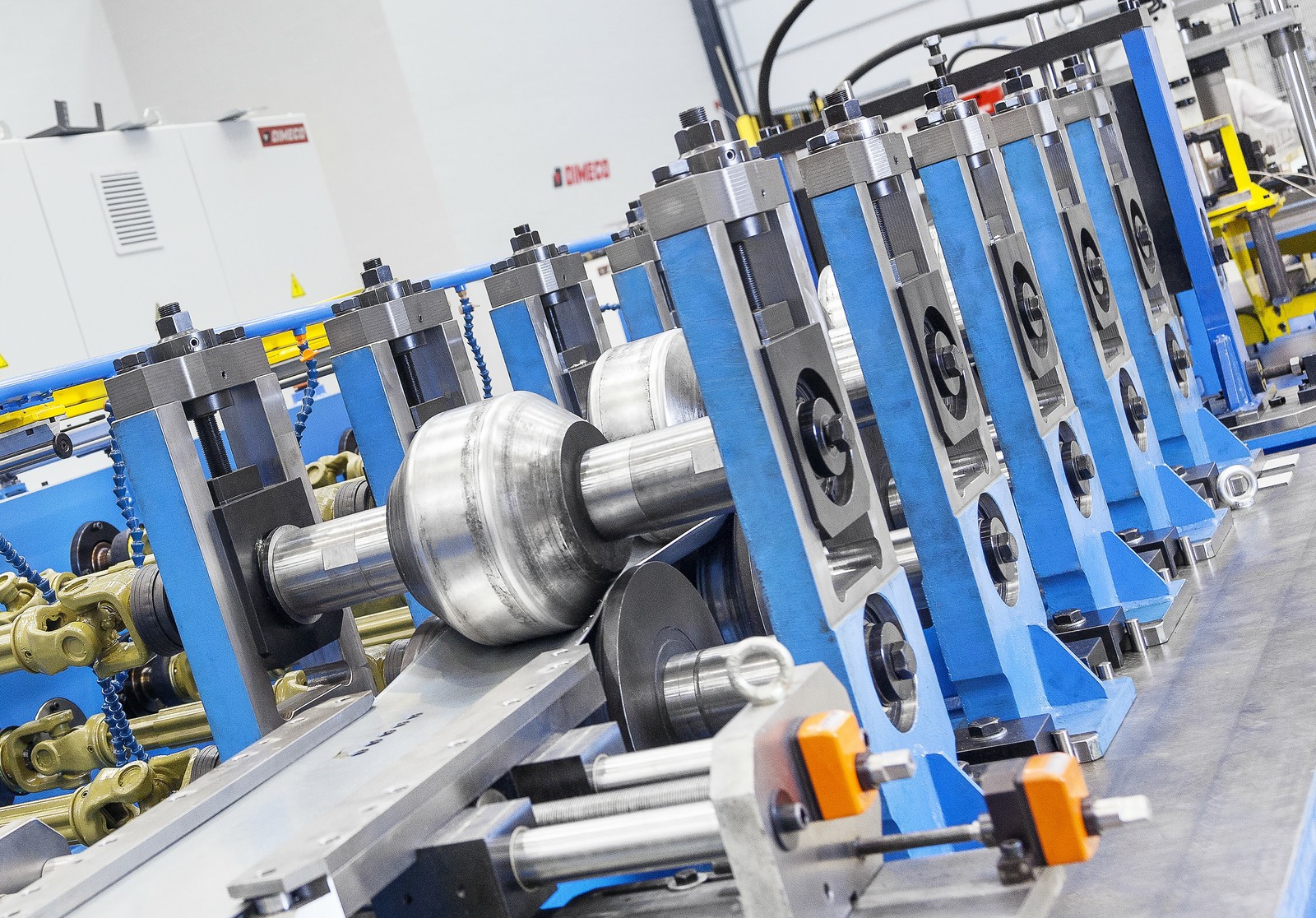

Machine vision refers to the use of cameras, sensors, and software to automatically inspect and analyze products on production lines. Unlike human inspection, machine vision offers unparalleled accuracy, speed, and consistency by leveraging sophisticated image processing algorithms.

By integrating hardware and intelligent software, machine vision systems capture real-time data to detect defects, measure dimensions, and verify assembly accuracy, enabling manufacturers to maintain impeccable quality standards.

Why Zero Defects Matter in Manufacturing

Zero defects is a quality management philosophy aiming to minimize errors and flaws in products. Achieving zero defects leads to:

- Reduced waste and rework costs

- Increased customer satisfaction and loyalty

- Enhanced brand reputation

- Compliance with industry standards

- Optimized production throughput

Traditional inspection methods often fall short due to human error and limitations in speed. This is where machine vision systems step in as a reliable solution to detect defects at early stages and maintain product integrity.

How Advanced Machine Vision Systems Achieve Zero Defects

1. High-Precision Defect Detection

Machine vision systems utilize high-resolution cameras and advanced lighting techniques to capture detailed images of products. Using powerful algorithms, these systems can identify minute defects such as cracks, scratches, misalignments, or missing components that might be missed by human inspectors.

2. Real-Time Quality Monitoring

Unlike manual inspection, machine vision continuously monitors products during production. This immediate feedback loop allows operators to halt or adjust processes instantly when defects are detected, preventing defective batches from progressing further.

3. Consistency and Objectivity

Human inspectors can be inconsistent due to fatigue or subjective judgment. Machine vision eliminates variability by applying uniform criteria across all inspected products, ensuring objective and repeatable evaluations.

4. Integration with Automation

Modern machine vision systems seamlessly integrate with automated production lines. When defects are found, robotic arms or reject mechanisms can automatically remove faulty products, maintaining smooth workflow without manual intervention.

5. Data Collection and Analytics

Machine vision doesn’t just detect defects; it collects valuable data for analysis. This data helps identify root causes of defects, monitor trends, and improve overall manufacturing processes.

Key Components of a Machine Vision System

- Image Acquisition: Cameras and lighting capture high-quality images.

- Image Processing Software: Analyzes images to detect anomalies and verify quality.

- Hardware Interface: Connects vision system to production equipment for real-time actions.

- User Interface: Provides operators with inspection results and controls.

Applications of Machine Vision in Industry

Machine vision systems are widely applied across industries such as:

- Automotive: Inspecting parts for dimensional accuracy and surface defects.

- Electronics: Detecting solder joint defects and component placement errors.

- Pharmaceuticals: Verifying packaging integrity and label accuracy.

- Food & Beverage: Ensuring product consistency, packaging correctness, and safety.

- Textile: Detecting fabric defects and color consistency.

Benefits of Implementing Machine Vision Systems

- Increased Quality Control Efficiency: Inspects hundreds of units per minute.

- Cost Savings: Reduces scrap, rework, and warranty claims.

- Improved Product Reliability: Detects defects early to ensure only high-quality products reach customers.

- Enhanced Traceability: Maintains detailed inspection records for compliance and audits.

- Scalability: Easily adapted to various production sizes and complexities.

Challenges and Solutions in Machine Vision Implementation

While machine vision offers significant advantages, manufacturers may face challenges such as:

- Initial Cost: High upfront investment can be mitigated through ROI analysis demonstrating long-term savings.

- Complexity: Requires expert setup and maintenance, often addressed by partnering with experienced vendors like Sciotexe.

- Lighting and Environment: Proper lighting design is critical for reliable image capture; customized setups ensure optimal performance.

Why Choose Sciotexe for Machine Vision Solutions?

At Sciotexe, we specialize in delivering state-of-the-art machine vision systems tailored to your manufacturing needs. Our expert team ensures seamless integration, from system design to deployment and ongoing support. By choosing Sciotexe, you harness the power of advanced machine vision to drive your zero-defect goals and stay ahead of the competition.

Conclusion: Take Your Manufacturing to Zero Defects with Machine Vision

Achieving zero defects is no longer a distant dream but an attainable reality with advanced machine vision systems. These technologies empower manufacturers to enhance quality control, reduce waste, and improve operational efficiency. By integrating machine vision into your production line, you set a new standard for product excellence and customer satisfaction.

Ready to eliminate defects and boost productivity? Partner with Sciotexe today and transform your manufacturing process with cutting-edge machine vision solutions. Our website is your ultimate source of valuable information.

FAQ

Q1: What industries benefit the most from machine vision?

A1: Machine vision is beneficial in industries like automotive, electronics, pharmaceuticals, food & beverage, and textiles due to its ability to perform high-speed, accurate inspections.

Q2: How does machine vision improve quality control compared to human inspection?

A2: Machine vision provides consistent, objective, and real-time defect detection, eliminating errors caused by fatigue or subjective judgment common in human inspection.

Q3: Is implementing machine vision expensive for small manufacturers?

A3: While initial costs may be significant, the long-term savings through reduced waste, rework, and improved product quality often justify the investment. Sciotexe offers scalable solutions to suit different budgets.

Leave a Reply