Introduction

In today’s fast-paced industrial landscape, the demand for custom metal fabrication services is on the rise. Whether you’re in construction, automotive, aerospace, or any other sector, having access to high-quality metal fabrication can make a significant difference in your project’s success. At FAB-U-TECH INDUSTRIES, we specialize in providing tailored solutions that meet the unique needs of our clients. In this article, we will explore six essential custom metal fabrication services that can elevate your projects and ensure they stand out in a competitive market.

What is Custom Metal Fabrication?

Custom metal fabrication refers to the process of creating metal structures and components tailored to specific requirements. This involves various techniques, including cutting, bending, welding, and assembling metal materials. The versatility of custom metal fabrication allows businesses to create unique products that meet their exact specifications, enhancing functionality and aesthetics.

1. Precision Laser Cutting

One of the most sought-after custom metal fabrication services is precision laser cutting. This technique utilizes high-powered lasers to cut through metal sheets with incredible accuracy. The benefits of laser cutting include:

- High Precision: Laser cutting can achieve intricate designs and tight tolerances, making it ideal for complex projects.

- Versatility: It can be used on various materials, including stainless steel, aluminum, and carbon steel.

- Reduced Waste: The precision of laser cutting minimizes material waste, making it a cost-effective option.

At FAB-U-TECH INDUSTRIES, we employ state-of-the-art laser cutting technology to deliver high-quality results that meet your specifications.

2. CNC Machining

CNC (Computer Numerical Control) machining is another vital service in custom metal fabrication. This process involves using computer-controlled machines to create precise metal parts. The advantages of CNC machining include:

- Consistency: CNC machines produce identical parts with high repeatability, ensuring quality across large production runs.

- Complex Geometries: CNC machining can create intricate shapes and designs that would be challenging to achieve manually.

- Material Variety: This service can work with various metals, including brass, copper, and titanium.

FAB-U-TECH INDUSTRIES utilizes advanced CNC machining technology to provide custom solutions tailored to your project needs.

3. Metal Welding Services

Welding is a fundamental aspect of custom metal fabrication, allowing for the joining of metal parts to create strong, durable structures. There are several welding techniques, including MIG, TIG, and spot welding. Key benefits of our welding services include:

- Strength and Durability: Properly welded joints provide exceptional strength, ensuring the longevity of your products.

- Versatility: Welding can be applied to various metals and thicknesses, making it suitable for diverse applications.

- Customization: Our skilled welders can create custom designs that meet your specific requirements.

At FAB-U-TECH INDUSTRIES, we pride ourselves on our welding expertise, ensuring that every project is completed to the highest standards.

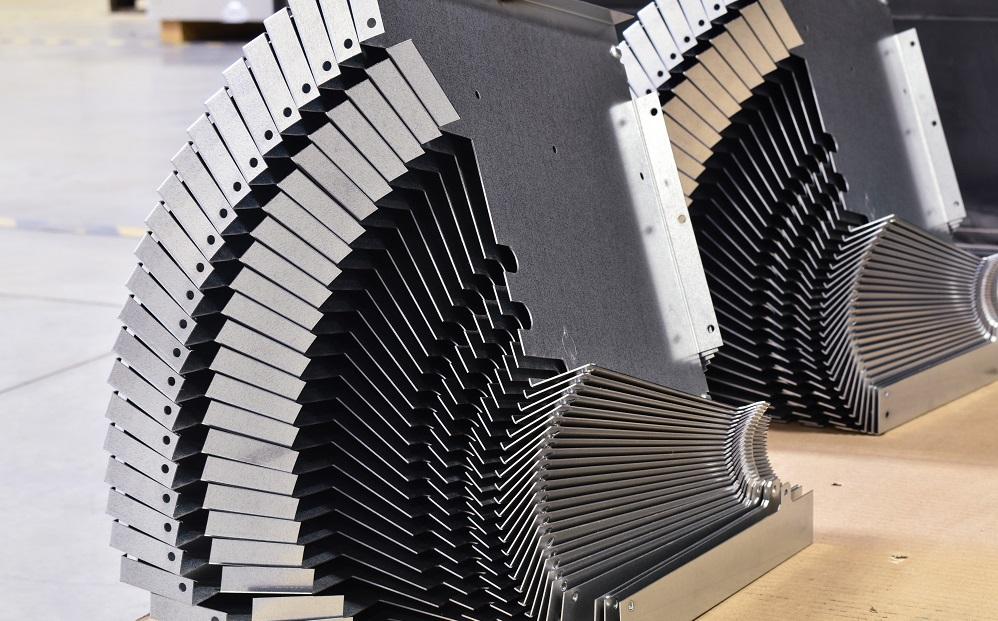

4. Metal Forming and Bending

Metal forming and bending are essential processes in custom metal fabrication, allowing for the creation of various shapes and structures. Techniques such as press braking and roll forming are commonly used. The benefits of metal forming and bending include:

- Design Flexibility: These processes enable the creation of complex shapes that enhance the functionality and aesthetics of your products.

- Material Efficiency: Metal forming can reduce waste by utilizing the material more effectively.

- Strength Enhancement: Properly formed metal components can exhibit increased strength and durability.

FAB-U-TECH INDUSTRIES offers comprehensive metal forming and bending services to help you achieve your desired designs.

5. Custom Metal Finishing

The finishing process is crucial in custom metal fabrication, as it enhances the appearance and protects the metal from corrosion and wear. Common finishing techniques include powder coating, anodizing, and plating. The advantages of custom metal finishing include:

- Aesthetic Appeal: Finishing can improve the visual appeal of your products, making them more attractive to customers.

- Corrosion Resistance: Proper finishing protects metal surfaces from environmental damage, extending the lifespan of your products.

- Customization Options: Various colors and textures are available, allowing you to create a unique look for your metal components.

At FAB-U-TECH INDUSTRIES, we provide a range of custom metal finishing options to meet your specific needs.

6. Prototyping and Design Services

Before moving into full-scale production, prototyping is an essential step in custom metal fabrication. This service allows you to test and refine your designs before committing to large orders. The benefits of prototyping include:

- Design Validation: Prototyping helps identify potential issues in your design, allowing for adjustments before production.

- Cost Efficiency: By catching design flaws early, you can save on material and labor costs in the long run.

- Faster Time to Market: Rapid prototyping can accelerate the development process, enabling you to bring your products to market more quickly.

FAB-U-TECH INDUSTRIES offers comprehensive prototyping and design services to ensure your projects are successful from the start.

Conclusion

Custom metal fabrication is an essential service that can significantly impact the success of your projects. By leveraging the six services discussed—precision laser cutting, CNC machining, metal welding, metal forming and bending, custom metal finishing, and prototyping—you can ensure that your products meet the highest standards of quality and performance. At FAB-U-TECH INDUSTRIES, we are committed to providing tailored solutions that meet your unique needs. Contact us today to learn more about how our custom metal fabrication services can elevate your projects. We cover everything in one place—don’t miss out on the latest insights.

FAQ Section

1. What materials can be used in custom metal fabrication?

Custom metal fabrication can utilize a variety of materials, including stainless steel, aluminum, carbon steel, brass, and copper, depending on the specific requirements of your project.

2. How long does the custom metal fabrication process take?

The timeline for custom metal fabrication varies based on the complexity of the project and the services required. At FAB-U-TECH INDUSTRIES, we strive to provide timely service without compromising quality.

3. Can I request a prototype before full production?

Yes, prototyping is a crucial step in the custom metal fabrication process. It allows you to test and refine your designs before moving into full-scale production, ensuring that your final product meets your expectations.

By understanding the various custom metal fabrication services available, you can make informed decisions that will benefit your projects and business. Reach out to FAB-U-TECH INDUSTRIES today to discuss your specific needs and how we can assist you!

Leave a Reply